Today’s most commonly used CNC machine can craft parts in three dimensions, also known as the X, Y and Z axes. Basically, this means the machine can work on objects going left/right, forward/backward and up/down. But on a 5-axis machine, you can rotate your part on an additional two axes, too. That is the essential difference between three-axis and five-axis machining. The advantages of 5-axis CNC are many, and we’ll explore them here.

Most shops refer to the rotational axes as either A and B, or B and C, though from shop to shop there may be a difference regarding on which two axes (X, Y or Z) you can manipulate the part. But the end result is the same, and the advantages of 5-axis systems are considerable. Here are just a few of the benefits:

Reduced Labor Cost Using 5-Axis Machines

One of the most important advantages of 5-axis CNC machining is that, in most cases, you can set up the material one time, add your programming and the tool does the rest. You need fewer (if any) fixture changes and fewer tool changes to get the job done. While the initial set up might take a bit longer than on a 3-axis machine, you rarely need multiple setups in a 5-axis environment. Fewer touches from a machinist translates into faster lead times.

More Accurate Parts

Faster turnaround is great, but you know you want parts that meet your specifications. Five-axis CNC uses shorter cutting tools. That means you can spin the end mill faster, with less vibration. Also, because the part doesn’t have to be repositioned in the machine, there is less chance of compromising the accuracy of your mills. If you think about it, it’s difficult to take a part out of its fixture, move it to a new setup, then re-place it so that it aligns perfectly with before. In the end, this translates into higher quality surface finish of your parts, and of course, greater accuracy.

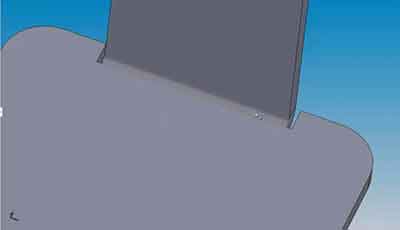

Manufacture Parts with Complex Geometry

Because the machine can take advantage of those additional two axes, it can create shapes that a 3-axis CNC machine can’t. These include creating arcs and special angles without having to reposition the part.

Five-axis machining is an ideal choice if you need prototypes or a very small run. Watching a 5-axis CNC machine in action speaks volumes, and it’s pretty cool, too.

Related Videos

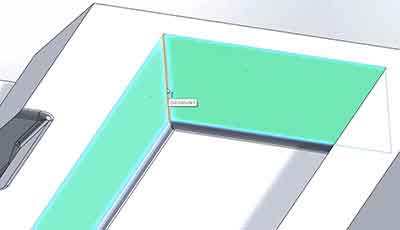

Two Tips for Mating Parts with Sharp Corners

China Manufacturing Corp. Prototype CNC Machining Video

For more great machining tips, download our CNC Machining Design Guide.