What is an Interior Fillet?

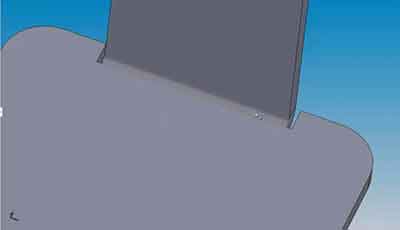

When you use CNC machining to create a part, you will get curved areas where end mills can’t create a sharp corner. Because end mills are round and spin around their length, a radius forms in the area where two sides of a part meet. This is an interior fillet.

Interior Fillets on Vertical Sides

Vertical radii are the most common form of interior fillet, located where two vertical walls meet. Select the correct radius for the depth of the feature in order to minimize lead time and maximize value. Optimally, you should design these with a depth that is no more than six times the corner radius. So, if your feature is 0.75” deep, a radius of .125” or larger is perfect. This would allow us to go in with a 1/4” end mill and remove material to form that feature. If you need a deeper pocket we can cut deeper, but cycle times will take longer and ultimately costs will go up.

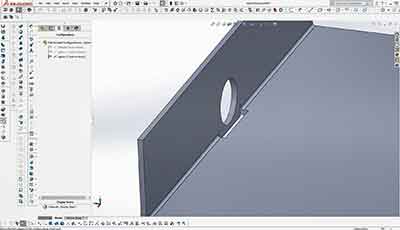

Where Wall Meets Floor

The second type of internal fillet is a radius between a horizontal floor and a vertical wall. This feature poses its own unique challenge because the tool used is dependent on the radius of the vertical wall fillet. If the vertical fillet is the same as the floor fillet, a ball end mill can be used. If the floor fillet is smaller than the wall fillet, go with a bull nose end mill. Of course, the easiest and most cost effective approach to horizontal wall fillets is not to have them at all.

Contoured Surfaces and Interior Fillets

Ball end mills are typically used on contoured surfaces. What this means is the larger the radii used, the faster the feature can be cut and you get improved surface finish. When you use larger ball end mills to machine the bulk of the part you may have to follow it with smaller tools. Watch out, though, because this usually results in undesirable witness lines and surface finish differences.

The Bottom Line

Interior fillets are an attractive feature on machined parts, but using the right tool to make them is important. It’s also important to remember that horizontal wall fillets, like ones you create along seams between floors and side walls, are difficult to achieve.

Related Videos

China Manufacturing Corp. Prototype CNC Machining Video

Designing 90-Degree Corners on 3-Axis CNC

Two Tips for Mating Parts with Sharp Corners