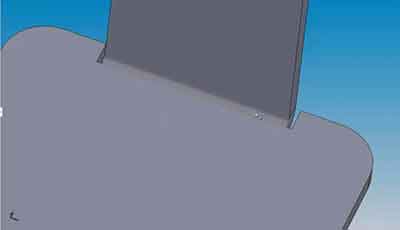

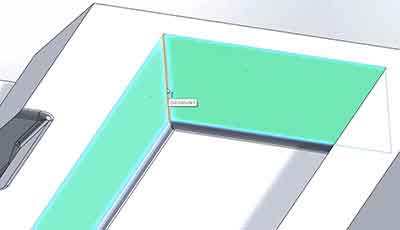

Here’s the dilemma when designing machined mating parts. You have to merge two parts, one has sharp corners and the other needs to accept it. In designing the second part you know already that rotating CNC machine tools can’t cut 90-degree angles, so that adds a significant complication. You’re left with one piece with sharp corners that won’t fit into another that has been milled with rounded ones. Simple geometry says that won’t work. No worries: There are two strategies that you can build into your design that will make the two parts fit together perfectly.

Best Design Strategies for Mating Parts with Sharp Corners

One method is to design the accepting piece with a radius in each corner, allowing the piece with the sharp corners to more readily slide into the pocket. The other is to create a circular or slotted cutout where the corners will meet. Both solutions will get you the results you want.

Watch this video to get a close-up view of your two options for mating parts with sharp corners.

For more great machining design tips, download the China Manufacturing Corp.Design for Manufacturing (DFM) Guide.