What is Bend Relief?

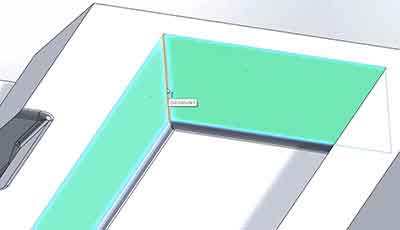

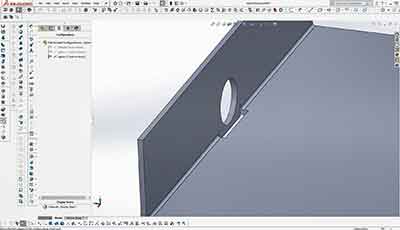

Take a piece of paper and try to fold just the middle inch of it to form a flap. Unfortunately, you can’t do it because the rest of the paper wants to fold up, too. To do it, you need a way to ensure that only that one inch width of paper can fold and leave the rest as a single, flat plane. That’s called sheet metal bend relief, and it’s important.

Bend relief is nothing more than two small incisions cut into a piece of sheet metal to free the metal in between. It separates the material you want to be able to fold from the rest of the part. You only need it when there is material on either side of a bend.

What Does Sheet Metal Bend Relief Accomplish?

As the video below clearly makes clear, adding bend relief is the only way to:

- Prevent tearing and deformation of your part caused by the press brake

- Separate bent and not bent elements of your part

- Ensure forming accuracy

How Do I Add Bend Relief in My Designs?

We often see designs come to us that don’t include bend relief. So, in order to successfully create your part, we add it to your design. But if you want to save time and money, it’s easy for you to add it yourself. All you need to do is add a cutout at least .030” wide and at least .015” past the end of the bend radius on either side of the bend on your part. It’s a tiny subtraction that means the difference between failed and successful part fabrication.

Related Videos

Sheet Metal Design Tips and Tricks

Why Sheet Metal Size Matters

Three Things You Need to Know about Forming Sheet Metal

For more great sheet metal design tips, download our Design for Manufacturing (DFM) Guide.