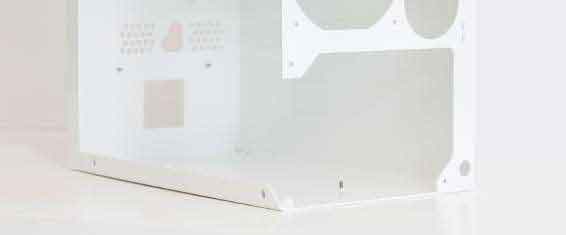

Sheet Metal Prototyping

Sheet metal prototyping works best for when form, fit and function are all a priority.

Sheet metal prototyping works best for when form, fit and function are all a priority.

How Does Prototype Sheet Metal Fabrication Work?

Sheet metal fabrication is the process of forming a piece of metal into a desired shape through bending, stretching, and removal of material. At China Manufacturing Corp., we use press brake punches and die tooling to bend and stretch flat stock into its final geometry. The sheet metal prototyping process is most often used when form, fit, and function are all a priority.

Typical sheet metal parts we manufacture include enclosures, brackets, assemblies, weldments, cabinets, and other components. Whether you need a single sheet metal part or 20 parts, we have the capacity to produce your sheet metal prototypes fast.

Average quote returned within hours

Instant Costing - Try ECMC, our free sheet metal costing CAD add-in

Standard ship on most projects of 7 work days or less. Expedites Available!

99+% on-time

99+% Quality rating

Get a quote using our hassle free part upload form!