Design for Manufacturing (DFM) isn’t just a random set of rules. Following DFM guidelines ensures that your sheet metal design flows through our processes without issues. This improves lead times and lowers your cost. The good news is that there are plenty of techniques you can use to ensure that your part is ready for manufacture.

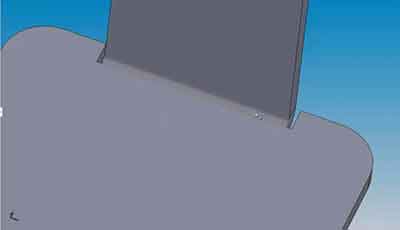

Hole Placement

Placing a hole too close to a bend could cause issues with forming and consistency. In the worst case scenario, it can lead to part conformance failure. But there are some options available, depending on the hole’s purpose. If you need a clearance hole for a tool or that allows wiring to slide through, try designing a slot, instead. A great idea to keep a round hole, is to design a tab that contains the hole, as you can see in the video. This will affect the bottom of the part, leaving a shallow tab of sheet metal below the hole.

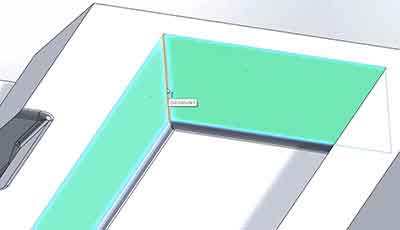

Unfolding Your Sheet Metal Design

If you use a standard bend radius (typically .030”) and your design unfolds without issues, you’re on your way to a faster manufacturing process. If your part includes internal features, taking the time to unfold the part during the design phase will save you delays later.

CAD Files and Sheet Metal Design

When you submit CAD models from SOLIDWORKS and other CAD systems for manufacture, it’s best to include a STEP file. Because your model drives the quote, your file should include any hardware, rivets or other fasteners that you need installed.

Before submission, save your part as a Step, AP203 or AP214 file. When we open the file, we’ll see all of the information needed to manufacture the part.

Following these simple guidelines will speed manufacturing time, so you’ll get your part back faster, and with lower labor charges.

Related Videos

Why Sheet Metal Size Matters

Three Things You Need to Know about Forming Sheet Metal

Why Tolerance Matters in Sheet Metal

For more great sheet metal design tips, download our Design for Manufacturing (DFM) Guide.