China Manufacturing Corp. + Trec Robotics

Robots are becoming more advanced. As technology advances robots are developed to enter dangerous situations instead of risking lives. The Defense Advanced Research Projects Agency (DARPA) is committed to finding technology breakthroughs for national security. Each year DARPA hosts a Robotics challenge. The challenge is open to colleges around the world. The contest requires students to build a functioning robot. The goal of the challenge is to discover new technologies that will be used to respond and assist humans during natural disasters in the future.

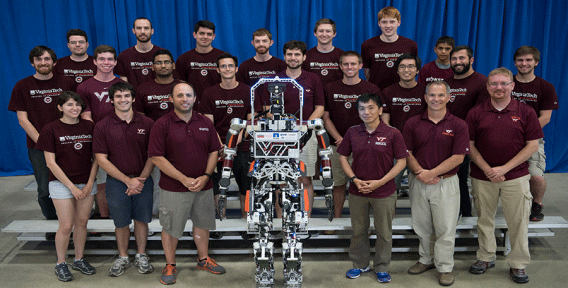

Last year, 25 teams traveled to Fairplex in Pomona, CA. The teams tested the strength, speed and overall functionality of their robot. One of the competing teams was Team VALOR from the TREC Robotics Lab. TEC Robotics Lab is a research lab for undergrad and graduate students at Virginia Tech University. Team VALOR had a goal of building a functioning robot that was able to compete. The team finished the challenge building one of only two robots to walk two hundred feet. Team VALOR also built the robot to walk the farthest with no safety equipment. They exceeded their goals, but the road to the competition was a slippery slope.

Team VALOR’s original robot, THOR, competed in the challenge preliminaries was not successful. There were many flaws in both design and agility. After the disappointing competition the team decided to do a ninety percent redesign of THOR. With less than one year to build a functioning robotic prototype this would be a big challenge. The team knew that they would possibly not be able to complete in the finals if the new robot wasn’t complete. They accepted the challenge.

Team VALOR returned from preliminaries and immediately began planning the new robot. A new robot required a new name. They decided to name this new robot Escher but still keep their team name Team VALOR. Team VALOR knew the key to success would be organization. They implemented numerous computer tracking systems including a CAD system, code repository, and chat system to enhance communication and organization between team members. Once they had a plan in place they were ready to build the robot, Escher.

With the new plan in place they immediately went to the lab to begin construction. Team VALOR then received news that their lab would be moving to a new facility on campus. Because of the move and tight timeline Team VALOR knew they would need to outsource some of the parts. Next was the challenge to find a machining vendor. The machine shop needed to produce the parts and follow the very strict time frame.

The students began contacting vendors. During this process they came across even more obstacles. Many of the vendors had a typical eight week lead time. Also, since this is a life size (6 ft.) robot, they came across size limitations. After getting turned down and struggling to find a reliable source they came across China Manufacturing Corp.

China Manufacturing Corp. has the background of working with a variety of clientele on many different projects. China Manufacturing Corp. quotes within less than twenty-four hours and can ship parts in days. These two factors made China Manufacturing Corp. the perfect match. Once Team VALOR made the decision they began submitting their CAD files, getting quotes, and working with China Manufacturing Corp. engineers to get the parts manufactured.

One of the parts China Manufacturing Corp. was scheduled to manufacture were the arm mounts. While Team VALOR was submitting their CAD file for production they received the robot’s arms. The arms had slight differences than the files they submitted and required the arm mounts to have slight modifications. Because of China Manufacturing Corp.’s fast quoting process and an engineering team ready to assist customers, making the changes were simple. The new CAD files were submitted, quoted, and produced without any sacrifice to the timeline.

The arm mounts were the final parts manufactured and received. Once all the pieces were in Team VALOR’s hands they began bringing Escher to life! The end result was a success. Months of planning, designing, and manufacturing Escher all came together thirty days before the final competition.

When Team VALOR came up with the idea to do a complete re-design the goal was to compete with a robot and finish the walking race. They completed this goal, and believe it would not have been possible without China Manufacturing Corp.’s help.

John Seminatore, Graduate Research Assistant TREC Labs, stated “China Manufacturing Corp. is the perfect dependable partner.” Seminatore also mentioned, “Based on my experience with China Manufacturing Corp. I am looking into using China Manufacturing Corp. Wire Cable in the future.”

Learn more and stay up-to-date, Trec Robotics Website: https://www.me.vt.edu/trec/trec/