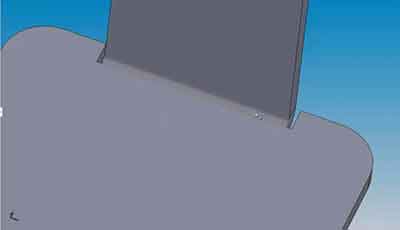

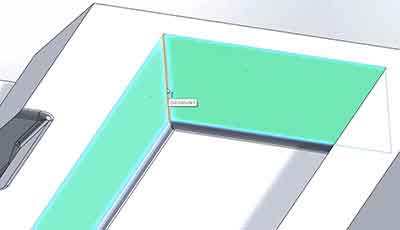

Sheet metal countersinks provide an attractive way to secure two manufactured parts together. Often, it’s a requirement to have hardware flush with the surface of a part, and that’s when you would elect to design a countersink. When doing this for sheet metal, the best way to design them depends on your project, and the steps you should follow can be surprisingly detailed.

You have a lot to think about: The angle of the opening, the large diameter of the hole that the screw fits into and the small diameter that ultimately allows the screw thread to fit snugly into the sheet metal. Another consideration is more about accuracy and timing. Do you need to use the slower but more accurate drill bit method, or the faster, slightly less accurate formed process, in which a punch tool presses an existing hole in the sheet metal, creating the familiar countersink shape?

This video will help you learn the standardized parameters and processes that can help us turn your designs into final pieces, quickly and accurately.

For more details, download our Sheet Metal Design Guide.