Five Reasons You Want Your Part Manufactured Using the Waterjet Cutting Method

China Manufacturing Corp. Machining has recently reconfigured the manufacturing floor and purchased new equipment to offer customers a Waterjet Cutting service. There are many benefits and reasons a prototype part could be manufactured on a Waterjet machine versus a CNC machine or lathe machine. This blog will highlight five reasons you want your part manufactured using the waterjet cutting method.

ACCURACY

Because the waterjet machine uses an ultra-high pressure water pump combined with an abrasive garnet material, the machine is able to cut through material with one pass. The accuracy of the waterjet is +/- 0.010”, and because the tool is a steady stream of water, the Waterjet never dulls.

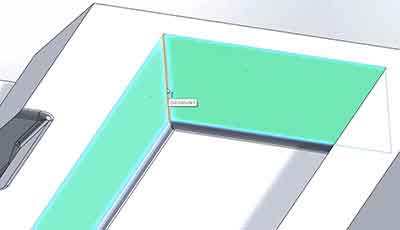

REPEATABILITY

Waterjet machines are powered by a motion control system. Combine the control system with the accuracy of cutting and the waterjet is capable of accurate cuts with a degree of 0.010” repeatability over a range of materials and shapes.

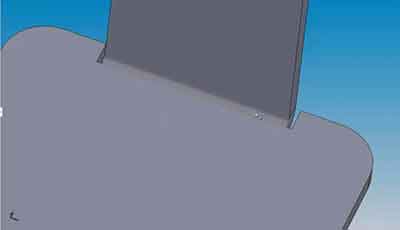

COMPLEXITY

Waterjet parts are not confined to straight-line geometries. Part complexity is only limited by the motion control system.

NO THERMAL DAMAGE

The use of water eliminates friction between the metal part and tool. This eliminates thermal damage or heat-affected zones on parts.

ENVIRONMENTALLY FRIENDLY

Waterjets are very environmentally friendly machines. They produce no hazardous waste, and because of the precision of manufacturing parts, material utilization is maximized reducing material waste.

Overall, waterjet cutting is a great process to manufacture prototype machine parts, and for production quantities. To learn more about China Manufacturing Corp.’s waterjet capabilities visit the Waterjet Service’s Page.