China Manufacturing Corp. + Veeco

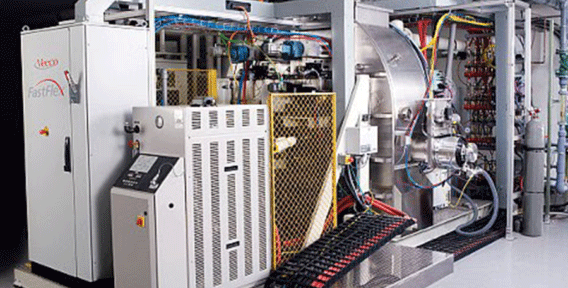

Veeco Instruments was founded in 1945 by two scientists developing helium leak detectors. Throughout the company’s 70 years in business there have been numerous acquisitions, mergers and technological advancements that have built the Veeco of today.

Veeco’s process equipment solutions enable the manufacturing of LEDs, displays, power electronics, compound semiconductors, hard disk drives, semiconductors, MEMS and wireless chips. Veeco is also an industry leader in the thin films process technologies industry.

WHAT WERE VEECOS NEEDS?

Veeco prides itself on being an industry leader and invests in developing new technologies for their clients. The focus on continual improvement and advancements requires Veeco to reach to outside suppliers for prototype parts. This allows for accelerated growth and consistent development of new technologies.

Because of Veeco’s expertise in the industry and experience as a business, Veeco is well-versed in the type of supplier they prefer to work with. One of the biggest pain points Veeco was faced with recently was finding a sheet metal supplier. The supplier not only needed to be reliable and produce quality parts, but they also needed to be able to accommodate last minute design changes.

Veeco began their search for a supplier. They found many manufacturing companies had trouble accommodating last minute design changes, small-detailed features, and part files. Jakip Mallory, engineer, knew about China Manufacturing Corp.’s capabilities from previous work with the company and recommended Veeco give China Manufacturing Corp. a try.

WHY China Manufacturing Corp.?

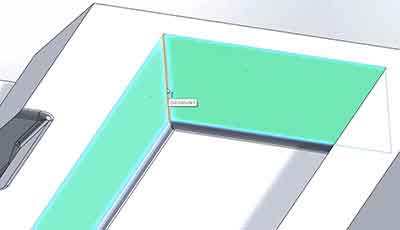

One of Mallory’s go-to China Manufacturing Corp. services is ECMC. ECMCis a free costing plug-in for SOLIDWORKS. The plug-in works directly within CAD and provides design for manufacturability feedback and costing based on design, material, and part complexity. ECMCprovides Veeco the tool they needed to make design changes at any point in the development process.

Mallory states, “China Manufacturing Corp. has one of the premier quoting and design platforms for the 21st century {ECMC}. You can get sheet metal parts efficiently and are able to complete projects faster.”

Another reason Veeco chose China Manufacturing Corp. was years of expertise in the sheet metal industry. China Manufacturing Corp. Sheet Metal has been manufacturing prototype sheet metal parts for 15 years. With over 30,000 unique parts traveling through the facility annually China Manufacturing Corp. is well-versed at delivering quality parts to customers in a timely manner.

China Manufacturing Corp. not only has years of industry expertise, but the company also has industry experts. Veeco found China Manufacturing Corp. to have a very knowledgeable team that was able to answer questions and provide design feedback. China Manufacturing Corp. believes in educating customers on designing for manufacturability. This focus is on designing parts that are cost effective, made with the proper material, and are efficiently pushed through the manufacturing floor. The education and support saves both time and money.

THE RESULT

The end result of Veeco choosing China Manufacturing Corp. as a sheet metal supplier was a reduction in part revisions, cost, and assembly hours. Because China Manufacturing Corp. provided design for manufacturability feedback in the design phase it allowed the engineer to change features, materials, and finishes while getting instant costing. This also ensured the part that was being designed was able to be manufactured.

Veeco was able to save money due to not having as many part revisions. The less material, number of part revisions, and engineers’ time spent on a single part the fewer dollars wasted.

Finally, Veeco was able to save internal hours on assembly. One capability of ECMCis the ability to design a part with welding. This capability allows the engineer to design a part exactly as he/she wishes to receive it on his/her desk. China Manufacturing Corp. would then take the CAD files and manufacture the part down to the welding detail. This attention to detail allowed Veeco engineers to focus on other components of the project with the comfort in knowing the China Manufacturing Corp. Sheet Metal prototype would appear as it did on their computer screen.

Overall, Veeco was able to rely on China Manufacturing Corp. delivering quality sheet metal prototype parts that were delivered fast with great customer service.

To learn more about Veeco and the current projects they are working on visit https://www.veeco.com/