China Manufacturing Corp. + Monterey Bay Aquarium Research Institute

The Monterey Bay Aquarium Research Institute (MBARI) is a nonprofit oceanographic research center that focuses on the entire ocean from surface to the seafloor. MBARI was founded by David Packard in 1987 with a mission to be a world leader in ocean science and technology for both advanced research and education. The organization now has over 220 scientists, engineers and staff dedicated to their mission and focused on research in one of the most diverse bodies of water.

Since MBARI focuses on marine science and technology from the surface to ocean floor the organization operates a variety of research vessels and vehicles. Currently MBARI has 3 research vessels. One vessel primarily operates locally, providing access to the Monterey Canyon. Monterey Canyon is one of the deepest underwater canyons in the United States and home to both a diverse biology and a complex continental plate formation. A second vessel travels up and down US West Coast conducting deep ROV dives and collecting oceanographic data.

MBARI operates both tethered and untethered underwater vehicles. Remotely operated vehicles (ROVs) are managed by individuals in a research vessel at the sea surface. These roam the ocean floor and collect video and samples. The samples are brought back to the research team to give researchers better understanding of the biology, geology, and chemistry of the deep sea. MBARI also operates autonomous vehicles. These are self-propelled using propellers or changes in buoyancy the glide underwater. The autonomous vehicles capture information about ocean chemistry and biology data, as well as collecting video and mapping the seafloor.

BEFORE WE HEAD TO SEA

Before any robotic vehicle or instrument is brought out to sea there are a team of engineers and researchers developing the systems. When an engineer designs anything that will be submerged into water there are numerous factors that need to be considered.

Size- Every extra cubic inch of space on a vehicle is increased weight. The increased weight can add cost to projects, especially if a vehicle is making a trip around the world.

Integration – All the components need to work together, and being in a confined space means lots of integration. The design of each component needs to fit exactly as planned and all the parts need to work together both in and out of water.

Immediate Success – Since time is of the essence and technology is consistently advancing the majority of the time there is one try to get the entire system correct. This means one prototype, and it sometimes means even skipping the prototype phase.

DESIGNING A PROTOTYPE

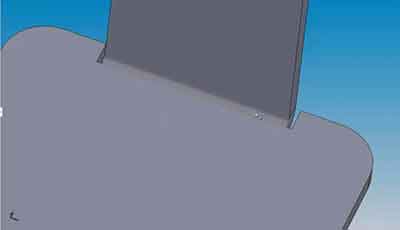

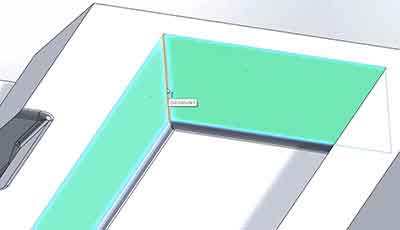

One prototype part that is consistently being designed is a sheet metal enclosure for the electromechanical assemblies. To design the enclosures the engineers use SOLIDWORKS. The platform allows the engineers to design and build the complete assemblies digitally.

A plug-in the engineering design team uses is ECMC. ECMCis a SOLIDWORKS plug-in that instantly costs sheet metal prototype parts. Aside from providing cost feedback the plug-in also provides design for manufacturing feedback. This alerts the engineers that there are manufacturing issues with the part. Some of the issues alerted include holes to close to an edge and non-uniform wall thickness. The alerts allow the engineer to make the necessary changes so when the part is ordered it is able to be manufactured without any surprises.

FULFILLING A MISSION

Because of the use of today’s technology the engineering team is able to save time and money when manufacturing prototype parts for the vessels. The team saves time by leveraging technology to avoid hand drawing parts. This ensures the part is built to the exact specification in the digital files. With such tightly integrated hardware and software the precision is vital.

Because MBARI is saving time the team is also saving cost. The ability to design and manufacture one part without having to go through multiple iterations keeps projects on deadline. When vessels are being shipped globally the deadlines are instrumental in making sure the vessels make it into the ocean.

Finally, because of today’s technology and the continual focus on innovation MBARI is able to fulfill their mission of being the world center for research and education in marine science and technology.

To learn more about MBARI and their current research explorationsvisit https://www.mbari.org/