China Manufacturing Corp. + bb7

bb7 is a full service product development firm located in Madison, Wisconsin. The company employs over 50 people with capabilities in all aspects of new product development: research, design, engineering, product testing, and much more. The team has designed a variety of products including medical devices, consumer electronics, and scientific equipment. With over 70 years of experience, bb7 is poised to help its clients overcome some of the biggest product development challenges.

THE LATEST INNOVATION

One of the recent client’s bb7 worked with was Isomark. Isomark is an established start‐up that grew out of technology developed at the University of Wisconsin. The global team of scientists’ study stable carbon isotopes in exhaled breath. Isomark’s original bench-lab process required breath samples to be collected in the field and shipped to Isomark’s headquarters for study. Isomark knew there was a more streamlined process, and the team began inventing a new system. This new system would be a “must-have” medical instrument for hospitals and would provide immediate results.

DESIGNING MEDICAL DEVICES

Isomark and the team began working on the new diagnostic instrument. While the team was building the innovation they secured an investor meeting. The meeting required Isomark to have functioning, complex, and attractive prototype quickly to meet the investors fast time line and our desire to show our vision through compelling prototypes in light of growing interest. Isomark contacted bb7 to assist in solving some of the design challenges.

Isomark and the team began working on the new diagnostic instrument. While the team was building the innovation they secured an investor meeting. The meeting required Isomark to have functioning, complex, and attractive prototype quickly to meet the investors fast time line and our desire to show our vision through compelling prototypes in light of growing interest. Isomark contacted bb7 to assist in solving some of the design challenges.

bb7 took the original Isomark assembly and immediately began to strategize. bb7’s team knew they needed to organize the electronics and cables, minimize the machine’s footprint, create a secure enclosure, and design to attract investors from the hospital sector.

The next steps included designing the prototype and contracting manufacturers for the parts. The key with finding the right manufacturers would be time. The design phase was impacting the timeline, and the massive number of internal components required a last minute order of the sheet metal enclosure.

FINDING A SHEET METAL SUPPLIER

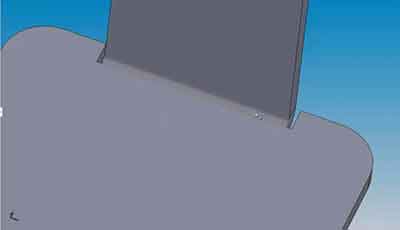

The team knew the enclosure would be sheet metal as they began sourcing a vendor. One of the Senior Engineers on the project was Greg Falendysz. Falendysz has years of experience designing in SOLIDWORKS, designing sheet metal prototype parts, and designing assemblies. When Falendysz saw that he was working with such a unique sheet metal enclosure he chose his reliable sheet metal supplier, China Manufacturing Corp.

Falendysz has used China Manufacturing Corp. on numerous sheet metal prototype projects. The reason he continually chooses China Manufacturing Corp., “good quality parts fast.” Falendysz stated, “For us it is all about time. We knew we could get parts quickly. Plus, I can’t say enough about the quality.”

SHEET METAL FABRICATION

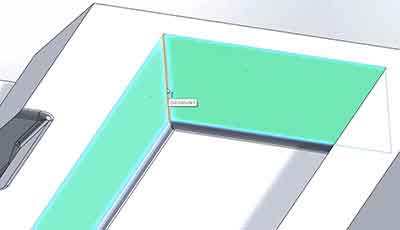

Once China Manufacturing Corp. Sheet Metal was chosen to be the fabrication shop Falendysz began the quoting process. During the design phase Falendysz used ECMC, a SOLIDWORKS plug-in that instantly costs sheet metal parts. ECMCallowed Falendysz to analyze how the design affected the part cost and get the initial estimate on what to anticipate as a cost.

During the design stage Falendysz also needed to include large radius bends (not a standard feature) to keep within design intensions. He worked with China Manufacturing Corp.’s engineers to execute the unique design. This allowed for communication about expectations and to ensure both teams were on the same page. The project was subsequently submitted for manufacturing.

THE END RESULT

The two sheet metal enclosures were fabricated and shipped to the customer within days. Falendysz said the parts arrived on-time and looked even better than he had envisioned. Overall, the project was a success. The clients received the completed prototype prior to their first investment pitch, and are looking forward to turning the prototype into a hospital “must-have.”

To learn more about bb7 and the other industries they serve visit https://www.bb7.com/